How to fix a carburetor

4 min read

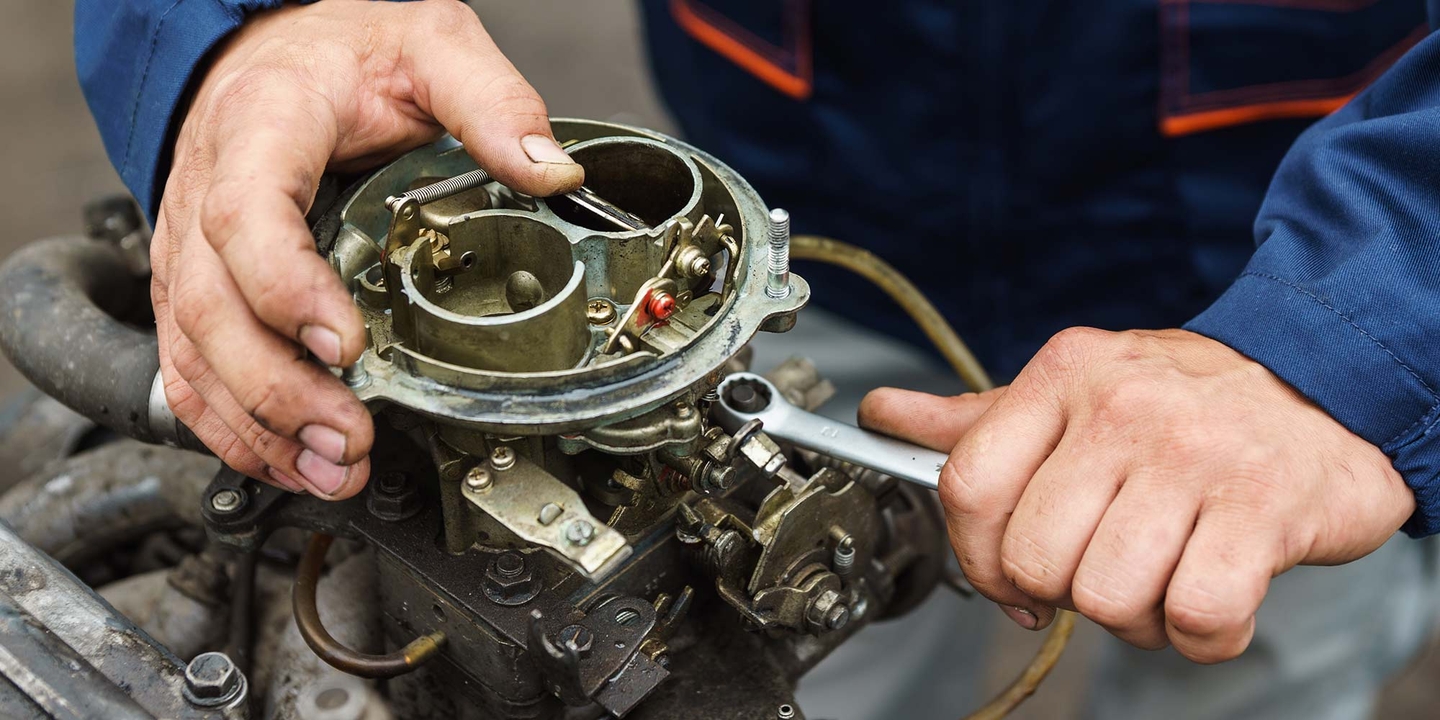

One of the most problematic and least-understood parts of any classic car is its carburetor. Everything else on your classic car is ready to drive, but one little ailment from the carb spells poor drivability, and a certain headache for whoever is behind the wheel. Not everyone can fix a carburetor. Fewer still have any inclination to work on one but understanding how they work goes a long way toward easing frustration when problems arise.

First, it’s important to understand a basic carburetor diagram. Then familiarize yourself with the carburetor parts and their function. Once you have reviewed the diagram and parts, you can work on basic carburetor repair troubleshooting.

Understanding a simple carburetor diagram

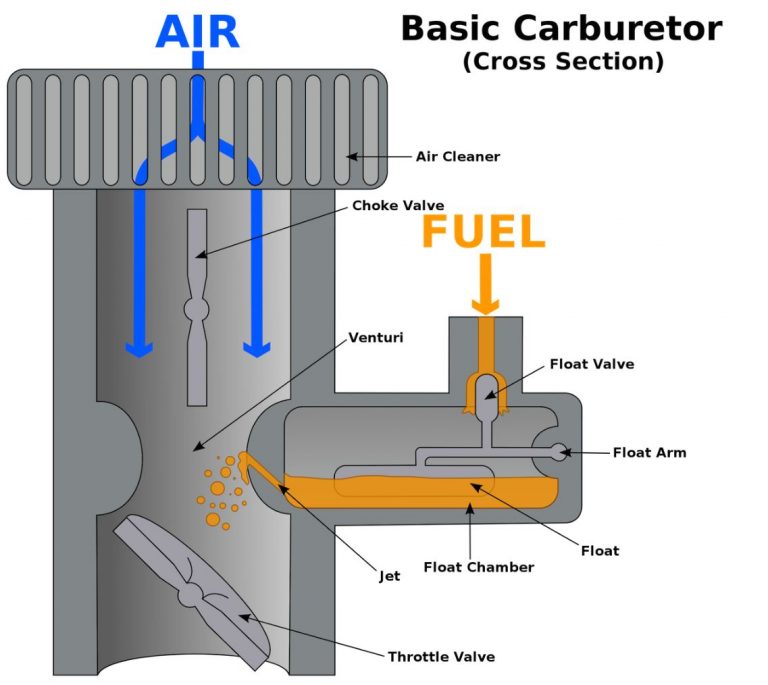

Air enters through the top of the carburetor (or the side, or the bottom, depending upon the carburetor’s design) on its way to the intake manifold and eventually the combustion chamber of each cylinder. The carburetor’s throat, bore, or barrel, is the passage which the air passes through. See the blue arrows in the carburetor diagram below.

A necked-down section of this passage, narrower in the middle and wider before and after — is called the venturi. As air rushes through this restriction, it speeds up. The change in speed as the air flows through causes the pressure to drop, drawing gasoline through a tiny feed in the side of the venturi. The goal is to atomize the fuel into a fine mist, which mixes with the passing air and continues to the intake manifold.

Once air and fuel move through the venturi, they encounter another obstacle called the throttle plate, a disc that opens and closes to control the amount of air entering the engine. The throttle plate is the part that moves when you press your foot on the accelerator pedal. The carburetor does the rest with different tube sizes and the presence or absence of a vacuum created by changes in pressure.

If the carburetor parts are working the way they should, the ideal ratio of air-to-fuel for efficiency, by weight, is 14.7:1. The rate and ratio that fuel and air enter the engine depends upon what the driver wants from the engine.

Carburetor parts and function

Several variables also come into play. For starters, when you snap the throttle plate open suddenly on a running engine, the vacuum drops almost to nothing for an instant causing the engine to stumble. Most carburetors employ an accelerator pump, essentially a gasoline squirt gun that shoots fuel into the throat of the carburetor to enrich the air-fuel mixture before the engine vacuum returns.

A carburetor’s fuel supply system is a miniature version of the car’s fuel system. There’s a tank, some plumbing, and an outlet. The tank is known as the bowl. There’s usually a hinged float inside that moves up and down with the fuel level. When the fuel level in the bowl is low, the float sinks, opening a valve that allows more gasoline into the reservoir. From there, it passes through a metering orifice called a jet into the various fuel nozzles.

Carburetors can be classified into two groups: those that utilize a metering jet and moveable rod assembly—like the Rochester Quadrajet—and those like a Holley that employs a metering jet and power valve. The goal for both systems is the same, giving the carburetor the ability to adapt to the varying idle, off-idle transition, cruise, and wide-open throttle conditions.

In the metering rod and jet system, the jet sits in a fixed location and will flow a given amount of fuel when unrestricted. The rod—which is small and tapered—moves in and out of the jet to vary the fuel levels to the carburetor’s mixing systems. In carburetors that employ a power valve, there is still a metering jet that controls most of the fuel control. However, a small valve opens under wide open throttle conditions to deliver extra fuel for maximum power.

Carburetor repair and troubleshooting

1. Gather safety equipment

Before you begin, ensure you have a fire extinguisher handy when working with open fuel sources. Wear safety glasses and clothing made from natural fibers (which won’t melt to your skin if you should catch fire).

Get the fuel to spark

To check fuel delivery, remove the fuel line where it enters the carburetor and use a length of rubber hose to direct the flow into a bottle or similar container. Fuel should pulse out in strong spurts if your engine has a mechanical fuel pump (electric fuel pumps are more of a steady stream). Dispose of it in a flame-proof container when you no longer need it. To check for a spark, crank the engine with a spark plug wire pulled and grounded to the engine block with a screwdriver or a piece of metal.

At 1/16 to 3/32 inches, you should see a blue spark between the metal and the block. (Don’t touch the metal, or you’ll feel an uncomfortable jolt.)

Check for vacuum leaks

They’re invisible and the bane of anyone fixing a carburetor. First, look for cracked or disconnected hoses. With the engine running, spray starting fluid around the base of the carburetor and intake manifold. If the engine speeds up a little, you likely have a leak near the last place you sprayed the fluid and will have to fix it. Cracks will need repairing, and if the base of the carburetor (where it mates with the intake manifold) is warped, it may be time for a new or professionally rebuilt one.

Make sure the accelerator pump works

Does the accelerator pump work? With the engine off, look into the carburetor’s throat and work the throttle linkage by hand. Does a fine spray fan out near the top of the throat? If so, the accelerator pump is probably doing what it’s supposed to be doing. If not — or if it drips or dribbles — the seals inside the pump may have deteriorated and need replacement.

It isn’t impossible to fix a carburetor; it just takes patience, attention to detail, and plenty of research to learn which parts you’ll need to replace, how you should clean them, and how they all go back together. Don’t assume that a carburetor rebuild kit has all the parts you need, and don’t be afraid to do a practice run or two on a simple carburetor that you don’t plan on using on your engine. If you’re more inclined to take your carburetor to a professional for service or repair, that’s certainly an option.

Keeping your classic car running well requires mechanical knowledge and a lot of love and care. Whether it’s you’re buying your first classic car or you’ve bought so many you know the best way to sell a classic car, consider keeping your car protected with classic car insurance.